Revolutionizing Theater Seats: Where Style Meets Customization

Discover Artisan Theater Seating’s Commitment to Crafting Stylish, Customizable, and Unique Seating Solutions for the Perfect Theater Experience.

The Angelo.

Quilted Leather, Ultimate Style + Comfort.

Ultra-Refined Details.

Contrasting chocolate brown stitching adds a finishing touch.

Furniture as Fashion

We totally blame the world of “internet search theater seats” for creating a perception with consumers, and even more so with the design trade that “all theater seating is ugly,” and we hear that a lot, and we do understand why people might have that opinion.

It simply doesn’t have to be that way!

Currently, the vast majority of our seating business comes to us through our industry partners in the design trade. We do our best to listen and respond to the input and suggestions of our design partners, as we continually aspire to evolve our design skills as it applies to our ability to offer all our customers something that is genuinely unique, and absolutely stylish.

The theater seats, chairs and sofas we are designing today are a world apart from where we began this journey. Done at a high level of design, the aesthetic contribution that unique and stylish seating brings to the overall look and feel of a theater room is enormous. In our role as skilled theater builders, we always work the room design process with the goal of maximum concealment of any and all of the electronics elements in the room, such that the eye is drawn to the “pretty things” in the room.

Theater Seats Customization

Unless we are starting from a true clean sheet of paper, working with an architect to design “the perfect room,” we are frequently challenged to properly fit the amount of seating in the room that the customer desires. We will discuss this element in greater detail in “Our Process,” but suffice it to say that this is typically our starting point in the theater seats customization process.

Mixed Materials

This certainly falls into the style part of what we do, in our constant quest to offer our customers theater seats that are unique to their design desires and become legitimate one-of-a-kind pieces of furniture.

We do approximately 70 percent of our projects in one of our many choices of high-quality premium leather. Not every project we do is a “jaw dropper,” and many, many people are very happy to purchase seating that is of the highest build quality, covered in a beautiful, durable high-quality leather, in a traditional color (even black), or perhaps in a color that they didn’t know existed. Not everyone is looking to make a statement with their theater seating.

That said, for those who do want to do something that is unique and stunning with their theater seating, working with our manufacturing partners, we dominate this segment of the category.

For this customer, we often use upholstery rather than leather, and in many projects, we used mixed materials, which could be upholstery with wood, (standard or exotic species), or even upholstery with wood and leather. In terms of materials options, the selection is genuinely infinite, and however large the breadth of our offering with leather is concerned, the options with upholstery dwarf it by comparison.

We’re in the business of creating and selling best in class theater seating, and it all adds up one chair at a time (8 chairs is our average order size). We’re just as happy doing a traditional style and configuration in one of the many popular shades of brown or gray, but we do like to be challenged on the design side, because we know that we can bring a customer’s visualization to life and deliver a finished product that will exceed even the highest expectations.

Pure Custom Theater Seats

Does it have to include a cupholder?

Going back to all the work that we do with the design trade, and the notion of “furniture as fashion,” the question of the inclusion of a cupholder as a mandatory part of the chair’s design is something we get asked quite frequently. It might seem like an insignificant detail (of which there are absolutely none!), but it rather is positioned front and center.

The simplest answer is that “no, you do not have to include a cupholder,” (but if you do want cupholders, we can provide them in sleek brushed stainless, in multiple color options. We could also powder coat to sample if that is of interest).

That said, the standard 3 ¼” theater seats cupholder does provide a useful application, albeit not without some shortcomings. It will hold a Diet Coke or Miller Lite, or a bottle of your favorite Octoberfest beer. It will even hold a full-size Solo Cup, but at the end of the day, it is still a cupholder in the arm of a beautiful and often custom designed theater seat, and there are many designers and homeowners who just can’t get past that, no matter whether it is powder coated to match the upholstery or not.

The “what the cupholder won’t hold” question is also a part of the conversation, and would include amongst other things, a big bowled red wine swirling glass, a square cut crystal double old fashioned cocktail glass (square peg in a round hole), and certainly not a bottle of champagne! Just saying.

To say that we have customers for whom these considerations are important is a significant understatement, and fortunately our discovery process always includes a question and discussion of this design element.

Believe this if you will, but we have absolutely secured business on our creative capabilities and solutions in this area alone!

When we find ourselves in the design process with a “no cupholders please” customer or designer dictate, we have turned to our partner Fortress Seating for solution options, which are always pure custom.

Our two most repeatable solutions are using what we call an “inset tabletop,” which is positioned in the chair arm in a similar location to a cupholder, but is so much more than a cupholder. The other solution, if there is available width in the chair row dimensions, is to design and fabricate a completely custom console table, to be positioned between the chairs. In the “no cupholders please” world, these console tables are the ultimate solution, in terms of both functionality and style.

We want to share two recent examples of each type of project, with an amusing irony that some of our most impressive custom work is not always about the chairs themselves, but our capabilities to address certain “lifestyle consideration requests” from our customers.

The Inset Tabletop

This is such a wonderful and elegant solution for the “no cupholders please” theater seats project.

In concept, it is simple. In the same general location as a cupholder would be positioned, the top of the arm is designed from the outset to have a recess created which can accommodate an inset piece of specifiable material (glass, wood, stone etc.), which when installed will sit just below flush in the chair arm (trying to mitigate “spill vulnerability” in any way possible). The overall dimensional footprint of this inset piece is completely flexible, (based on arm width), but suffice it to say that it is going to be much larger and exponentially more functional than a cupholder. For as much as we can offer seat bases at a fairly significant range of width sizes, it is still finite, based on the available width sizes of the motorization platforms. Arm width, conversely, is open ended and fully customizable, and we often extend the width of the arm from the standard five or six inches to something larger, specifically for the purpose of being able to create a larger inset tabletop piece. The increased usable space for the theater seats inset pieces using a seven-inch arm compared to a six-inch arm creates a surprisingly greater amount of usable space.

In our project example, this customer was someone who “self-identified” in the sharing of their very specific wants and needs. They made it very clear that they like to enjoy a full-bodied red wine out of a large bowled swirling glass and also be able to have the open bottle at the ready as well. After all, who wants to get up during the middle of a movie to refill their glass?

Stone was the customer’s choice for the material for the inset pieces. That said, neither Fortress Seating nor Artisan Theater Seating are in the stone cutting business, in which case Fortress provides the customer (customer’s designer) with a highly exact, three dimensional template which they then provide to their stone cutter for fabrication. Unfortunately, with this project, the stone pieces, of which there were six, were very inconsistent dimensionally with the template that had been provided. How then to best resolve this issue? Cutting the stone insets further created a risk of making the individual pieces too small, by reduction, such that the decision was made to fabricate each arm and inset with an even greater level of customization, such that the inset space in each arm had to be completely hand fabricated to accommodate the size nuance differences between the stone pieces. Wow!

The anomalies in the sizes of the stone insets added another four weeks to the build process, with multiple mock-ups and test fittings to get it perfect, which is always the only acceptable outcome for us and our manufacturing partners. We (Fortress!) absolutely got it perfect, with not a penny of additional upcharge to the customer, beyond the standard cost for an inset tabletop. We had agreed on a price, and we stood by it. It’s never quite as easy as it looks!

This is such a wonderful and elegant solution for the “no cupholders please” project.

In concept, it is simple. In the same general location as a cupholder would be positioned, the top of the arm is designed from the outset to have a recess created which can accommodate an inset piece of specifiable material (glass, wood, stone etc.), which when installed will sit just below flush in the chair arm (trying to mitigate “spill vulnerability” in any way possible). The overall dimensional footprint of this inset piece is completely flexible, (based on arm width), but suffice it to say that it is going to be much larger and exponentially more functional than a cupholder. For as much as we can offer seat bases at a fairly significant range of width sizes, it is still finite, based on the available width sizes of the motorization platforms. Arm width, conversely, is open ended and fully customizable, and we often extend the width of the arm from the standard five or six inches to something larger, specifically for the purpose of being able to create a larger inset tabletop piece. The increased usable space for the inset pieces using a seven-inch arm compared to a six-inch arm creates a surprisingly greater amount of usable space.

In our project example, this customer was someone who “self-identified” in the sharing of their very specific wants and needs. They made it very clear that they like to enjoy a full-bodied red wine out of a large bowled swirling glass and also be able to have the open bottle at the ready as well. After all, who wants to get up during the middle of a movie to refill their glass?

Stone was the customer’s choice for the material for the inset pieces. That said, neither Fortress Seating nor Artisan Theater Seating are in the stone cutting business, in which case Fortress provides the customer (customer’s designer) with a highly exact, three dimensional template which they then provide to their stone cutter for fabrication. Unfortunately, with this project, the stone pieces, of which there were six, were very inconsistent dimensionally with the template that had been provided. How then to best resolve this issue? Cutting the stone insets further created a risk of making the individual pieces too small, by reduction, such that the decision was made to fabricate each arm and inset with an even greater level of customization, such that the inset space in each arm had to be completely hand fabricated to accommodate the size nuance differences between the stone pieces. Wow!

The anomalies in the sizes of the stone insets added another four weeks to the build process, with multiple mock-ups and test fittings to get it perfect, which is always the only acceptable outcome for us and our manufacturing partners. We (Fortress!) absolutely got it perfect, with not a penny of additional upcharge to the customer, beyond the standard cost for an inset tabletop. We had agreed on a price, and we stood by it. It’s never quite as easy as it looks!

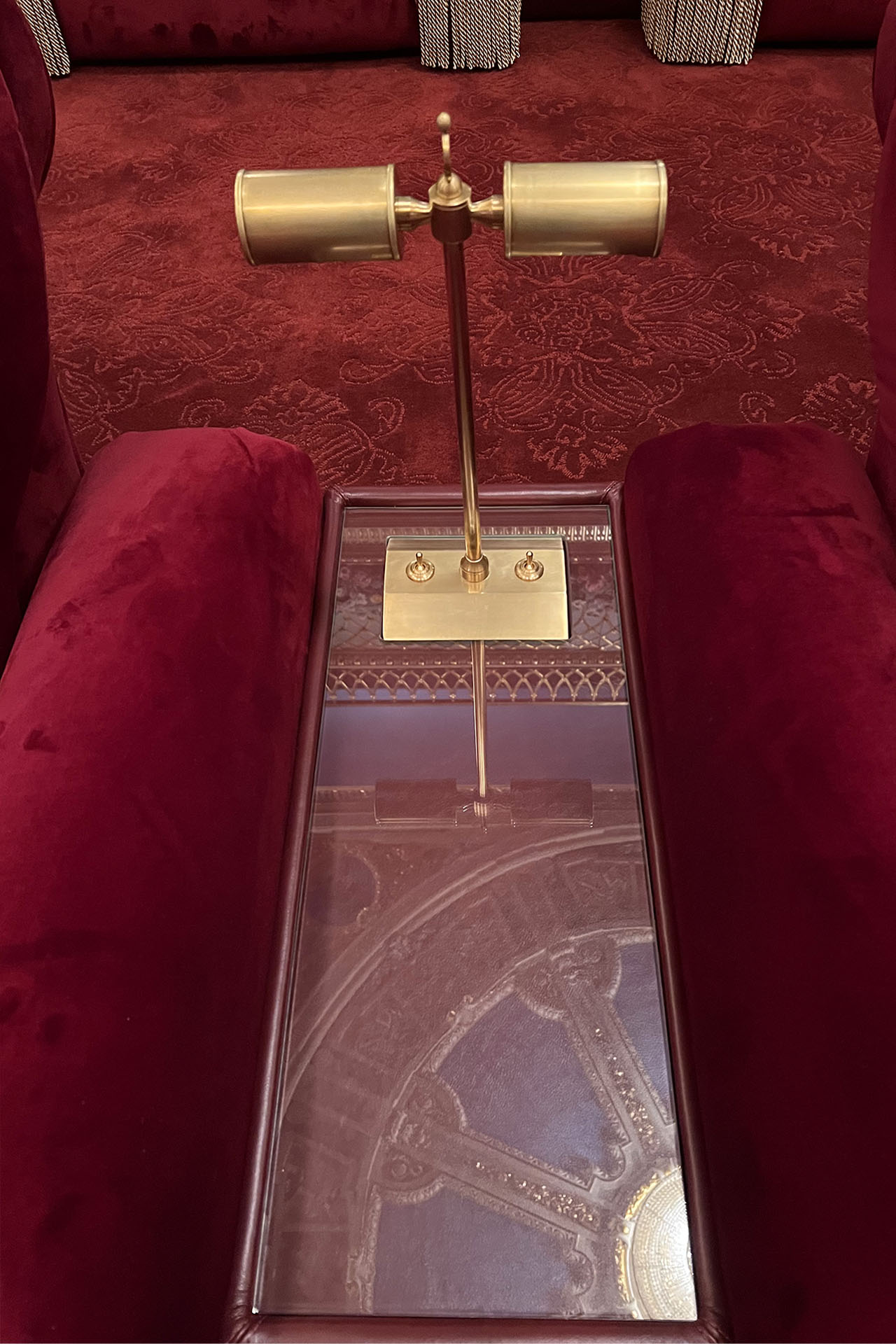

Console Tables

In another example of “it’s complicated,” we had a project where the chair row did have sufficient width to accommodate the customer’s desire for seating capacity and still include custom designed console tables to go between the chairs.

In the very simplest description, these console tables are “a box,” and yet it is so much more than a box! For this project, the designer had specified a sumptuous Italian velvet upholstery for the chairs, and a beautifully rich complementary leather for the console tables. We made the decision to use a custom sized glass inset piece on the tabletop, to protect the leather and serve as a giant “coaster.” All very straightforward design considerations, but…

Adding to the complexity of this console table design was that the designer had also included a specification for some very distinctive (and expensive) “bankers’ lamps” to be placed on each console table, for both aesthetic design considerations and also as an additional, dimmable “layer of light,” which we always think is a good idea.

At first discussion, it was both the manufacturers and designers suggestion that these lamps simply rest on the glass inset piece. It was our immediate concern that this created an enormous invitation to have all the lamps (of which there were many) “never be in the exact same place twice,” and we felt that this would simply not do in a room with this level of grandeur. With no offense to the housekeeping staff, the first time the lamps get lifted to clean the glass (which would likely be frequently) the lamps would be forever after be out of exact alignment. See some of our portfolio projects here.

Based on the mechanical engineering skills of our owner, Ken Walker, we proposed a completely different but more complicated solution to this theater seats design challenge. Our recommendation was to create a shallow recess in the leather tabletop inset, at a very precise depth and location, to create a means by which the lamp base could be physically “anchored” into the console table. We knew that to achieve this goal we would need a very tight fit, such that the lamps were snug and would be held securely in place. Our tolerance goal was 1/32”. Call us perfectionists.

The next element was to have the glass inset pieces have a perfectly matching cutout, to fit the lamp base with the same 1/32” tolerance in the theater seats. Lastly, we worked with the UK based lamp manufacturers’ US representative (across the corridor from our design studio in the Mart, with an enormous thanks to Laura Rozadowski at Ferrell Mittman for her amazing contribution to this project!). We asked the manufacturer to refabricate the lamp base to have the power cord exit through the bottom of the lamp, for an electrical connection inside the console table, rather than having the power cord exit out of the back of the lamp base, which would be the standard design, and drape over the back edge of the console table.

All told, between all the motorized chairs in the row and the lamps, we needed to power ten devices in each row. As an added element of concealment (one of our longtime specialties!), we created a chase for the entire chair row, such that all the power routing for the chair row (chairs and lamps) is completely concealed! Like magic.

This project was in the southeast US, and the customer was so impressed with our engineering design and execution of this specific element, that within less than 12 hours of being back on the ground at ORD, they contacted us and told us that they wanted the project to double the size of the original phase!

If you want custom, and I mean really custom, there is not another more skilled team than the collaboration of Artisan Theater Seating and Fortress Seating.